Table of Content

Once the spring is compressed, you can remove the old strut, install the new strut, or perform whatever other maintenance you need to do. When you are finished, loosen the compressor and allow the spring to expand back to its normal size. Once all the bolts are loosened and removed, the strut assembly should be free to come off. Generally, these shorter lowering springs lower the ride height and provide a more responsive and sporty feel due to their stiffer design. Continue to slowly jack up the LCA until you see the bolt start to protrude through the top strut mount.

Once you have reinstalled the strut onto the car, you can place the wheel back and tighten the lug nuts. You can then move to conduct the same procedure on the other side’s strut assembly. This process requires you to pay close attention to how the lowering springs are placed on the strut perch. If they are placed incorrectly, the holes are unlikely to line up when installing these lowering springs onto the strut assembly. The plates are pitched to match the slope in the helix of the spring.

Building your own spring compressor is possible, if done carefully

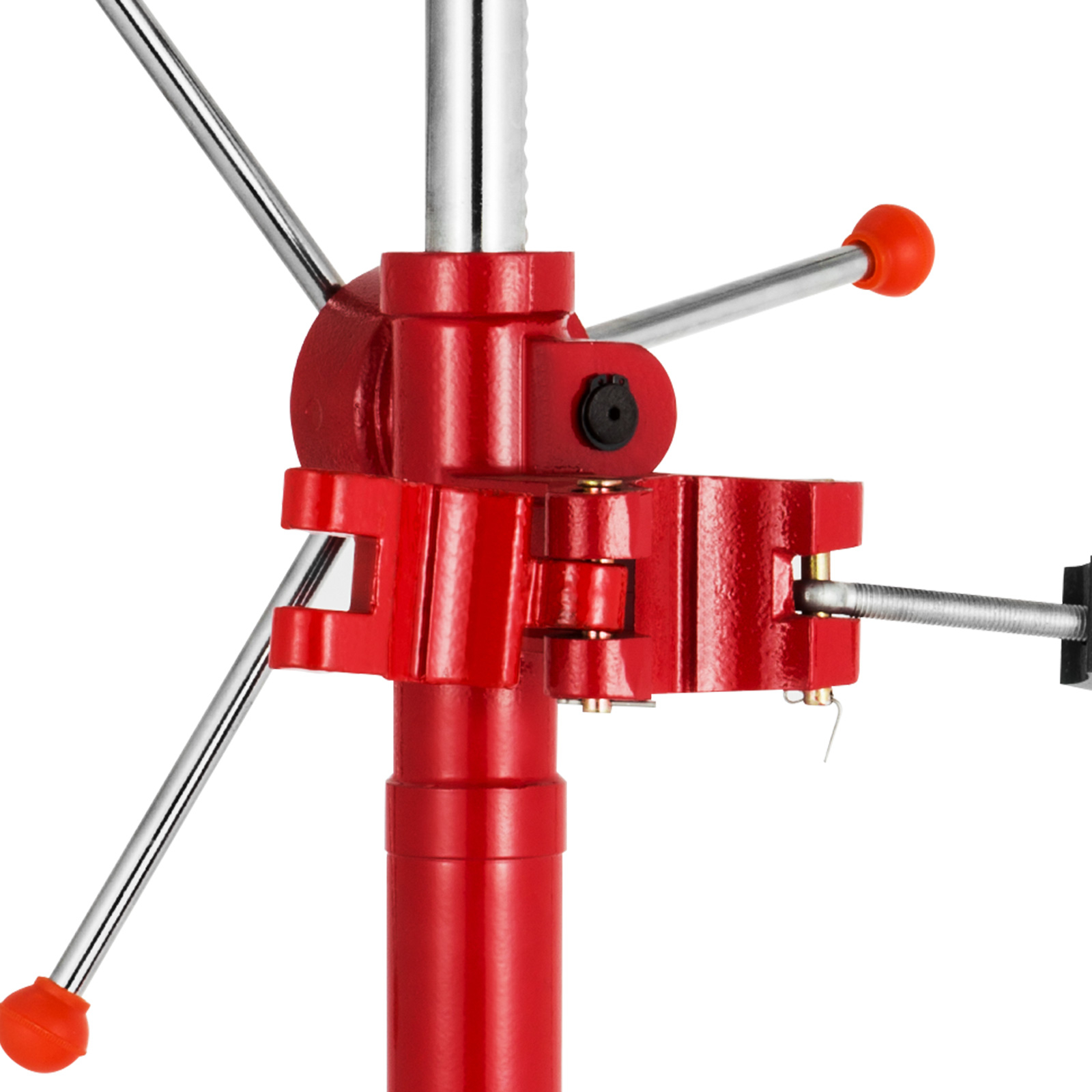

This is necessary when replacing the strut or performing other maintenance on the strut assembly. There are several different types of strut spring compressors available, but they all work in essentially the same way. The correct tool for performing a BMW front strut replacement is the plate, or “fork”, style compression tool. Unlike the hook style tool, the plate compressor uses only one threaded rod to retract two plates that “squeeze” the spring from top to bottom. Therefore, if you are simply replacing the entire shock assembly, then you can remove the three top mount nuts , and this will disconnect the strut assembly from the body.

As the spring settles, ride height decreases and causes undesirable changes in wheel alignment. Springs typically last a long time and, in some cases, can even last the lifetime of the vehicle. However, that doesn’t mean springs don’t wear and become worn out over time.

Can you retension a spring?

The ones I own are probably 40 years old, high quality, American made, and the claws are plenty long enough to wrap around the spring and hold it. I see that some of the new ones now being sold address the slippage issue by having pins that lock the claws in place around the spring. Use the strut spring compressor to compress the spring.

This Warren, Michigan company produces top-notch automotive diagnostic and repair tools. This OTC Clamshell Strut Spring Compressor is a simpler approach to MacPherson compressors. Slowly twist the rod or piece of wood until the coil is fully compressed. Now, take a ratchet and thread it onto the end of the rod or piece of wood. Compressing a strut spring without a tool may sound like a daunting task, but it is actually quite easy to do. All you need is a few household items and a little bit of patience.

How do you make a spring compress easier?

I figured that, for that price, it was worth it just for the adjustable shocks, and if the springs turned out to lower the car, it was gravy. So I bought them, and when they arrived, I had 14 days to build a spring compressor and disassemble and test all four shocks. Those springs are beefy enough that they support the weight of the car without bottoming out. And you need to compress the spring even further in order to remove the nut or retainer. For these reasons, you’ll often read that compressing springs is an inherently dangerous activity best left to professionals. Once the spring is seated, you’ll want to compress the spring using a vise or clamp.

This professional strut spring compressor is made of drop forged steel and has locking pins for safety. It's designed for use on most passenger vehicles, whether domestic or imported, as well as light trucks. Replacement parts are available, and it comes with bilingual instructions. To disassemble the pair, the spring must first be compressed. With MacPherson struts, there’s a housing with an integral bottom spring perch, and an upper perch plate and a bushing at the top that looks a bit like a man’s hat. The bushing contains a bearing, as the whole point of the design of a MacPherson strut is that it absorbs the shock as well as rotates when you steer the car.

Strut Spring Compressor Pricing

Then, simply tighten the clamp until the spring is compressed. If you don’t have a C-clamp, you can try using a length of pipe. Place the pipe over the spring and then use a wrench to twist the pipe, compressing the spring as you go. Using a pry bar, compress the spring by pushing down on the lower control arm. Place the floor jack under the vehicle and raise the vehicle until the spring is compressed. Once the spring is compressed, you can remove the jack and the spring will stay compressed.

Finally, reinstall the front end links to the steering knuckle and hand-tighten these snug. The lower ball joint to lower bracket nut needs to be reinstalled and torqued. Begin by disconnecting the front sway bar end links from the axle on both sides of the vehicle.

Also, it may slide a little bit more than you like, and there have been some complaints that on some larger vehicles it can't grab the spring with both hooks. The OEMTOOLS MacPherson Strut Spring Compressor kit is our pick for the Best Overall Strut Spring Compressor. This is an externally-mounted kit that locks onto the coils of a spring and compresses it for easy removal. Considered "the standard in the industry," this all-steel, premium product does not require any adapters and uses heavy-duty acme thread. It features versatile mounting options and multi-position hooks. It's easy to use, and the safety pins keep everything locked in place.

There are two sets of threaded rod, each with two hooks and pin detents to latch onto the spring coil. You have to work slowly and tighten each side a little at a time, but they can help you safely compress a spring’s height. These compressors are most often seen in repair shops, but they can be affordable for someone who does enough suspension work in their own garage. These strut spring compressors work with threaded handles on large bolts to compress springs for suspension work. These compressors only work on struts and springs that are not installed in a car. They can’t be used on a vehicle, so if you have to compress your spring inside of a wheel well, these are not for you.

Press up on the shock and move the LCA down so that the lower mount hole lines up with the LCA mount. Then insert the lower mounting bolt through and hand-tighten; you still torque this after the strut assembly is reinstalled. This will allow for articulation of the lower control arm , which will allow the LCA to rotate and provide additional room to remove/install the front shocks/springs.

You can leave the end link connected to the sway bar as you are mainly concerned about separating the sway bar from the steering knuckle. Changing the stiffness can be done by changing any or all of the variables that control spring stiffness. One easy way to do this is to add a second identical spring in series with the existing spring. Next, you will need to find something to use as a lever. Once you have the lever in place, simply apply pressure to the top of the strut with the lever.

No comments:

Post a Comment